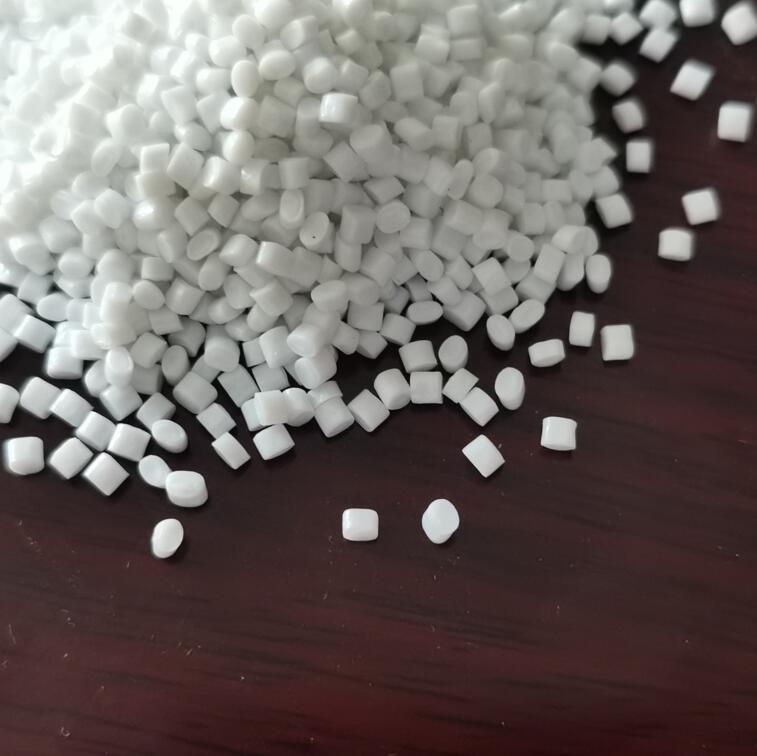

PBT

Properties Test Condition Test Method Unit Typical Value Physical Specific Gravity ASTM D792 - 1.42 Molding Shrinkage ASTM D955 % 1.2 ~ 2.0 Melt Flow Rate 250¡æ/2.16kg ASTM D1238 g/10min 18 Water Absorption ...

Read DetailsAddress: 318 Jinshui Road, Licang District, Qingdao City, Shandong Province

Properties Test Condition Test Method Unit Typical Value Physical Specific Gravity ASTM D792 - 1.42 Molding Shrinkage ASTM D955 % 1.2 ~ 2.0 Melt Flow Rate 250¡æ/2.16kg ASTM D1238 g/10min 18 Water Absorption ...

Read Details

PBT it is one of the advanced engineering plastics with high rigidity, high toughness, good fatigue resistance, weather resistance, low water absorption rate (all the properties maintain under moisture atmosphere including electrical properties), high dielectric ability, good electrical capacity, size stability, good formability, excellent anti-creep ability under high impact, and good chemical properties as well. It is easy to process into glass-fiber reinforced and flame-retardant products. PBT/PET can be ultrasonic welded and easily post-processed. ¡ñHigh toughness, high modulus, low creep ¡ñGood dielectric strength ¡ñGood dimensional stability ¡ñLow water absorption rate, good hydrolysis resistance ¡ñGood heat resistance, low coefficient of thermal expansion ¡ñHigh impact strength ¡ñResistance to Thermal aging ¡ñEasy to process PBT 605 Flame-retardant Polybutylene Terephthalate Characteristics Meet the environmental standards of RoHS and IEC, high gloss, UL94 V-0 flame retardant,good light shading and ag ...

Read Details

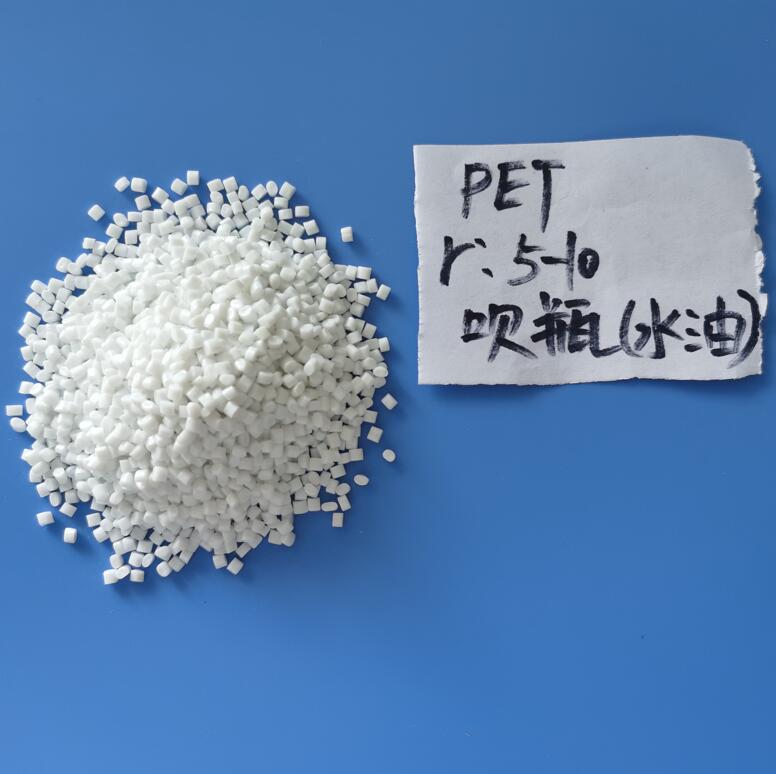

PET Resin is cream or pale-yellow crystal, with smooth and shiny surface. Resistance to creep deformation, fatigue resistance, abrasion resistance and dimensional stability are perfect. Small wear and tear but high hardness, its toughness is the largest in thermoplastic. The electrical insulation of PET is perfect and little be affected by temperature, however, poor corona resistance. PET is non-toxic, weather resistance, and anti-chemical stability is very good. PET is low water absorption, resistance to weak acids and organic solvents. Intolerance of hot water immersion and alkali. Item Unit Index I.V. dL/g 0.85¡À0.02 Crystallinity % ¡Ü60 Color value L - ...

Read Details

PET Resin is cream or pale-yellow crystal, with smooth and shiny surface. Resistance to creep deformation, fatigue resistance, abrasion resistance and dimensional stability are perfect. Small wear and tear but high hardness, its toughness is the largest in thermoplastic. The electrical insulation of PET is perfect and little be affected by temperature, however, poor corona resistance. PET is non-toxic, weather resistance, and anti-chemical stability is very good. PET is low water absorption, resistance to weak acids and organic solvents. Intolerance of hot water immersion and alkali. Item Unit Index I.V. dL/g 0.80¡À0.02 Crystallinity % ¡Ü60 Color value L - ...

Read Details

PET chip is TPA-based polyethylene terephthalic copolymer designed for various applications, especially for the bottle like drinking water & food container. It is a high molecular weight polymer. It is low acetaldehyde content, good color, viscosity stability and low heavy metal content features, excellent further processing features like low processing temperature, high clarity and little degradation. I tem Unit Index I.V. dL/g 0.775¡À0.02 crystallinity % ¡Ü60 Color value L -- ¡Ý 83 B Mpa ¡Ü -0.5 ...

Read Details

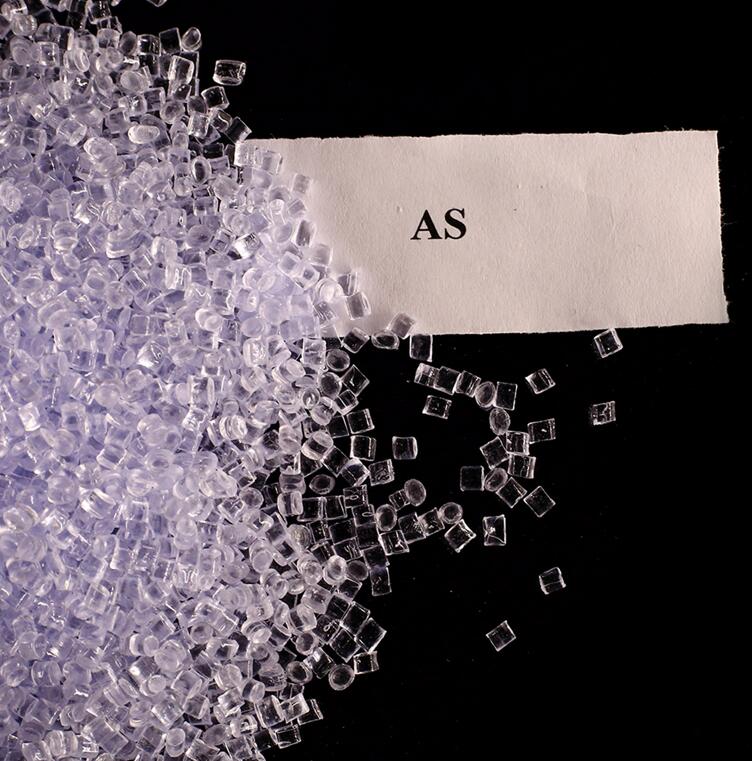

Acrylonitrile - styrene copolymer. A polymer composed of acrylonitrile and styrene.Typically 15-50% styrene.Transparent solid with yellow to amber needle color.The density of 1.06.It's thermoplastic.Not easy to change color.It is unaffected by dilute acids,bases, alcohols and gasoline.But soluble in acetone, ethyl acetate, dichloroethylene and so on.Can be used as engineering plastics.Excellent heat resistance and solvent resistance. Properties Test Condition Test Method Unit Typical Value Physical Specific Gravity ASTM D792 - 1.07 Molding Shrinkage (Flow), 3.2mm ...

Read Details

Acrylonitrile - styrene copolymer. A polymer composed of acrylonitrile and styrene.Typically 15-50% styrene.Transparent solid with yellow to amber needle color.The density of 1.06.It's thermoplastic.Not easy to change color.It is unaffected by dilute acids,bases, alcohols and gasoline.But soluble in acetone, ethyl acetate, dichloroethylene and so on.Can be used as engineering plastics.Excellent heat resistance and solvent resistance . Properties Test Condition Test Method Unit Typical Value Physical Specific Gravity ASTM D792 - 1.07 ...

Read Details

Polycarbonate (PC) is a molecular chain containing carbonate base polymer, according to the structure of the ester base can be divided into aliphatic, aromatic, aliphatic, aromatic, and other types.Because of aliphatic and mechanical properties of aliphatic and aromatic polycarbonate is low, which limits its application in the field of engineering plastics.There are only aromatic polycarbonate won the industrialized production.Due to the particularity of polycarbonate structure, has become the fastest growing in the five engineering plastics of general engineering plastics. 1.Properties PC is characterized by high transparency, high impact resistance, high hardness, high creep-resistance, excellent dimensional stability, good resistance to low-temperature and heat, flame retardance, ease to process, and excellent sound insulation Test Project Test Methods Unit ...

Read Details

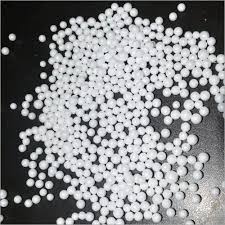

E. P.S. (Expandable Poly - Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS. These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups . F eatures l High strength, l Fast forming, l High foaming & oxygen index. Fire Retardant Grade Specification F301 F302 F303 F401 Beads Size mm 1.00-1.60 ...

Read Details

E. P.S. (Expandable Poly - Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS. These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups . F eatures l High strength, l Fast forming, l High foaming & oxygen index. High Expansion Grade Specification P301 P302 P303 P401 P501 Beads Size mm 1.00-1.60 ...

Read Details

E. P.S. (Expandable Poly - Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS. These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups . F eatures l High strength, l Fast forming, l High foaming & oxygen index. Specification E301 E302 E303 E401 E501 Beads Size mm ...

Read Details

Density(g/cm3) 1.2 Hardness(shore A) 60 Tensile Strength(Mpa) 11.6 Elongation at break (%) 335 Color Crystal ...

Read Details